FITINGS OF RESERVED FROM THE NEXT STAY IN THE SAMAR

APPLICATION OF REQUIRED FITINGS

Thread fittings are designed to create socket joints on the cylindrical thread. Their benefits:

- a variety of designs that allows you to create piping systems of almost any configuration;

- ease of installation, repair and maintenance of the connection;

- the possibility of multiple installation / dismantling and replacement;

- strength, reliability and durability of the connection.

REQUIRED FITINGS FROM THE COMPANY ALFA-STAR

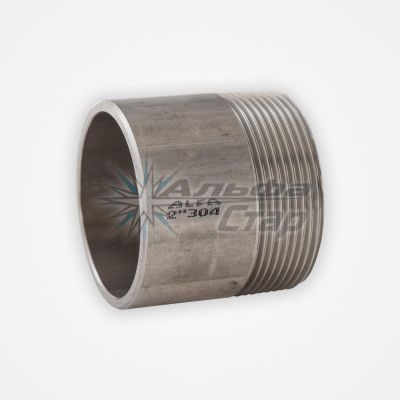

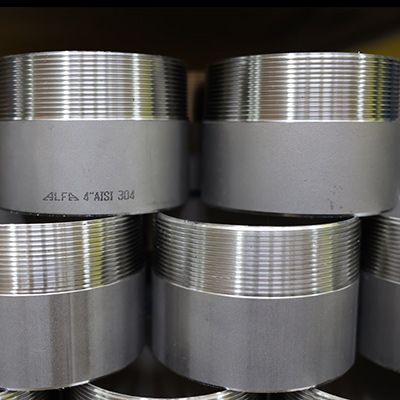

Our catalog contains threaded fittings made of AISI 304 steel ( 08X18N10 ), AISI 316 ( 03X17N12M2 ) according to DIN 2999 of the following types:

- Americans HP / HP and HP / BP, including those with the PTFE gasket, which ensures maximum tightness. Used in sections of the pipeline with high pressure and temperatures;

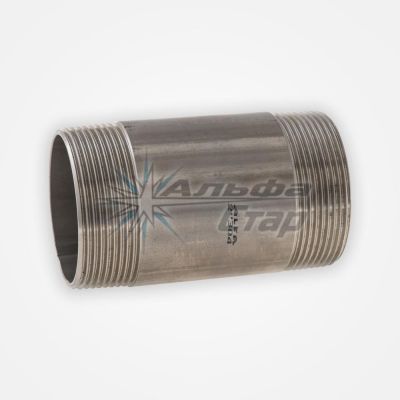

- barrels. Served for connecting fixed pipes and connecting equipment;

- stainless plugs HP four- and hex, BP ( cap ) to create dead ends in the pipeline. Can be used as tank covers;

- counter-huts to prevent threading;

- couplings of steel stainless BP are equivalent and transitional for connecting sections of the pipeline with the same or different diameters;

- welded nipples, hexagonal and transitional. Welded at one end are welded to the pipe, and the second is connected by thread. The hexagonal ones are designed for installation on a wrench, the transient ones serve to connect pipes of different diameters;

- 90 ° HP / HP and BP / HP outputs for changing the direction of the workflow;

- threaded and welded stainless steel. Welded at one end are welded to the pipe, the second is mounted on the thread;

- tees for the distribution of the flow of the working environment;

- futorks for switching from one thread to another;

- fittings for connection using a hose of equipment, measuring instruments, containers.