FLANDS FROM THE RUNNING STAY IN THE SAMAR

APPLICATION OF FLANCE

Flange connections are widely used in pipelines, building structures, mechanisms due to their strength, reliability and durability. Stainless steel flanges are resistant to aggressive media, high pressure ( up to 40 MPa ) and temperatures.

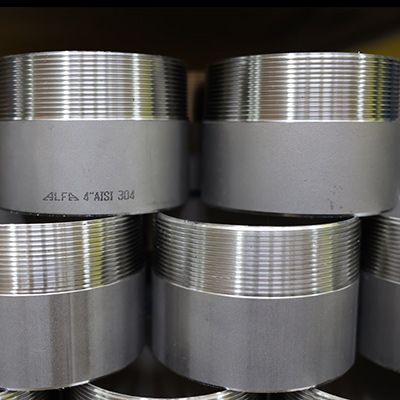

FLANTS FROM COMPANY ALFA-STAR

Our catalog presents the most common types of stainless flanges made of AISI 304 steel ( 08X18N10 ), AISI 316 ( 03X17N12M2 ), 12X18N10TH, 10:

- welded flanges DIN and GOST. They are welded to the ends of the pipes with two seams and tightened with bolts. A gasket is installed between the flanges to ensure maximum tightness and uniformity of pressure distribution. Hold the load up to 2.5 MPa;

- collar flanges DIN and GOST. They have a cone-shaped protrusion — collar around the circle of the hole, the end of which is welded to the pipe. High-hermetic connection works at a pressure of up to 40 MPa;

- free flanges are stainless and silomine. Connection is included, including also the ( board-chayba collar, ) selection. The collar's end is welded to the end of the pipe with a free flange worn on it. Flanges are pulled together by fasteners. Such connections are intended for hard-to-reach sections of the pipeline that need frequent repair and maintenance. Silumin flanges are cheaper, but less durable, so they are used in areas with a working pressure of up to 1 MPa;

- DIN and GOST flange plugs to block the flow;

- gaskets of steel and non-metallic DIN and GOST. Steel is used in tense sections of the pipeline; paronite, Teflon, EPDM gaskets are designed for less responsible areas.